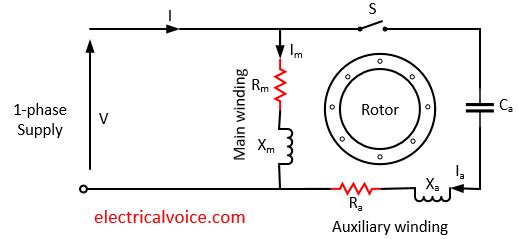

A Capacitor Start Induction Motor is a single phase motor consists of a stator and a single-cage rotor. The stator has two windings i.e. main winding and an auxiliary winding. The auxiliary winding is also known as starting winding. In construction, these two windings are placed 90° apart in space. The Capacitor Start Induction Motor is shown in figure 1.

The capacitor Ca is used in this motor to produce a greater phase difference between main winding and auxiliary winding currents.

Rm = main winding resistance

Xm= main winding inductive reactance

Ra = series resistor connected in the auxiliary winding

Xa = auxiliary winding inductive reactance

Ca = series capacitor connected in the auxiliary winding

S = centrifugal switch

Working of Capacitor Start Induction Motor

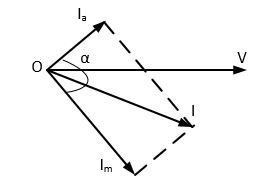

When the stator windings are energised from a 1-phase supply, the main winding carries current Im and the starting winding carries current Ia. The value of the capacitor Ca is chosen such that current Im is made to lag current Ia by 90°. Therefore, there is a 90° time-phase difference(α) and 90° space difference between the two currents. These two currents produce a rotating magnetic field which starts the motor.

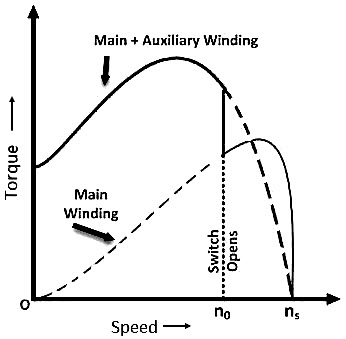

The main and auxiliary windings are connected in parallel during motor starting. When the motor reaches speed about 70 to 80 % of synchronous speed, the auxiliary winding disconnects from the supply by centrifugally operated switch S.

The phasor diagram for this motor is shown in figure 2.

The torque-speed characteristic of this motor is shown in figure 3.

Note:

1. The reversal of the direction of rotation of this motor is possible by reversing the line connections of either main winding or the auxiliary winding. This can be done when the motor is at standstill condition.

2. The starting torque is 3.0 to 4.5 times the full load torque. Hence starting torque is high. This torque is higher than a split-phase induction motor.

3. The electrolytic capacitors of the order of 250μF are used in this motor.

4. Capacitor Start Induction Motors are costly.

Applications

The Capacitor Start Induction Motor is suitable for higher inertia loads where frequent starts are required.

1. It is used to drive pumps and compressors.

2. It is used in the refrigerator and air conditioner compressors.

3. It is used in conveyors and machine tools.