Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs) are the microprocessor controller devices situated at the remote sites of the plant or at the field of the process systems. PLCs purpose is to monitor the process parameters located at the field and adjust the outputs based on the inputs received by the PLCs. PLCs will operate on any systems which will have input field devices that are the On-Off type (discrete or digital ) or analog input devices. Similarly, it will operate on the field devices which will be discrete or analog output type.

In simple words, Hence PLC acts as the interface between the input and output devices at the process side of the industries. It monitors the inputs received from the input devices and takes necessary output control functions by executing the programs stored in its memory.

The term Logic is used in Programmable Logic Controllers because all the program inside the PLC will be of Logic programming (eg: Ladder diagrams ).

In industrial applications, hard-wired relay logics were replaced by Programmable Logic Controllers due to its reliability, simplicity, low cost, easier programming and many other functions.

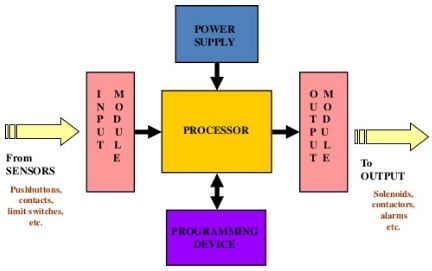

Block Diagram of PLC

The block diagram of programming logic controller (PLC) is shown in above figure. The PLC has following basic sections are

Processor section (CPU)

The processor section is the brain of PLC which consists of RAM, ROM, logic solver and user memory. The central processing unit is the heart of PLC. CPU controls monitors and supervises all operation within PLC. The CPU makes a decision and executes control instructions based on the program instruction in memory.

Input and output module

The input module is a mediator between input devices and central processing unit (CPU) which is used to convert an analog signal into digital signal.

The output module is a mediator between output devices and central processing unit (CPU) which converts a digital signal into analog signal.

Power supply

A power supply is provided to the processor unit, input and output module unit. The power supply may be an integral or separately mounted unit. Most of the PLC operates at 24 volts DC.

Memory section

The memory section is the area of the CPU in which data and information are stored and retrieved. Data Memory is used to store numerical data required for math calculation, barcode data etc. User memory contains user’s application program.

Programming device

Programming devices are dedicated devices used for loading the user program into the program memory or edit it and to monitor the execution of the program of the PLC. It is also used to troubleshoot the PLC ladder logic program. Handheld terminal (HHT) or dedicated terminal or personal computer is programming devices commonly used in most of the PLCs.

Applications of PLC

- PLC is used in civil applications such as washing machine, elevators working and traffic signals control.

- PLC is used in aerospace for Water tank quenching system.

- PLC is used for reducing the human control allocation of a human sequence given to the technical equipment that is called Automation.

- It is used in a batch process in chemical, cement, food and paper industries are sequential in nature, requiring time or event-based decisions.

- PLC is used in the burner management system to control the process of purging, pilot light off, flame safety checks, main burner light off and valve switching for changeover of fuels.

- It is used in the printing industry for multistage screen washing system and Offset web press print register control system.

- PLC is used in the travel industry for escalator operation, monitored safety control system.

Excercise

Q. What are different components in PLC?

Ans.

1. Input Interface

2. Memory Section

3. Central Processing Unit (CPU)

4. Programmable Language

5. Programming tool

6. An output Interface

Q. What are the advantages of PLCs than Hardwired Relay?

Ans. PLCs are highly reliable, easily programmable, Small and Inexpensive. PLCs can be designed with the communication capabilities so they can converse with the local or remote computer. They can sustain in a robust environment less maintenance.

Q. What is the programmable language used in PLC?

Ans. The general language program consists of Ladder Diagrams. Relay logic control scheme is represented in Ladder diagrams. Alternative languages use a Boolean representation of these control schemes as the base of the computer representation.

Q. What does Central Processing Unit (CPU) of PLC consists?

Ans. CPU is the brain of the system and consists of

Microprocessor: To carry out arithmetic and logical operations.

Memory: The area in the CPU in which the information is stored and retrieved.

Power Supply: The electrical supply that converts the ac voltage to various DC operating voltages.

Q. What is SCAN in PLC?

Ans. The sequential operation of the controller that goes through the ladder diagram from top to bottom of the ladder. In this process it updates all the outputs corresponding to the inputs. SCAN takes place from left to right of each rung. Usually, SCAN time is in milliseconds and it is a continuous process.