Buchholz relay is a special type of relay which is designed to detect the internal faults by monitoring the gas and oil movement in oil-immersed transformers. This relay is named after Max Buchholz in 1921. This relay is used in the transformer having the rating higher than 500KVA. Due to economic consideration, this relay is not used in the transformer having less rating.

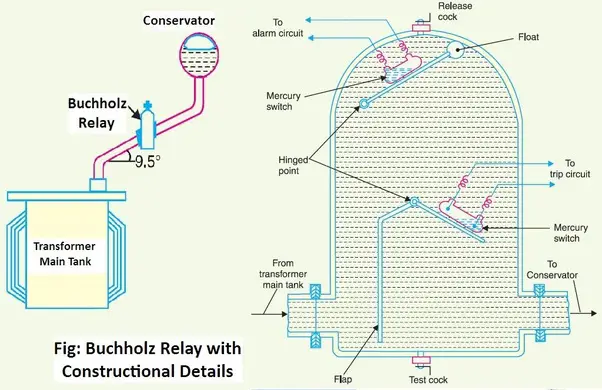

Buchholz relay is located in the pipeline connecting the transformer main tank and the conservator. As we proceed further, we will learn the construction and working principle of the Buchholz relay.

This relay is mainly used in oil-immersed transformer for providing protection against all types of internal faults. These internal faults could cause gas accumulation or strong oil flow in the oil circuit. These internal faults can be

- short-circuited core laminations

- bad contacts

- overheating of windings

- earth faults

- broken-down core insulation

- short-circuit between phases

- falling of oil level due to leaks

- puncture of bushing insulators inside the tank

- ingress of air as a result of a defective oil circulation system

Construction of Buchholz Relay

Buchholz relay is mainly connected in the pipeline between the main tank and the conservator tank in an inclined position as seen in fig. 1 (left side diagram). It is designed in the form of a vessel filled with oil which is dome in shape as seen in fig. 1 (right side diagram).

This relay is subdivided into two portions inside the vessel depending on its purpose and also its structure, i.e. the upper part and the lower part.

The purpose of this upper part is to alarm us about the faults. The upper portion of this relay consists of a flap that is hinged at one end and a float at another end. A mercury switch is placed on this flap. When there is movement is the flap due to the movement of oil then the terminals of the mercury switch makes contact with the alarm circuit’s terminal. This will close the alarm circuit and alarms us alert at the time of internal faults.

The purpose of this lower part is to detect serious faults. The lower portion of this relay consists of a flap that is hinged at one end and a float at another end. The flap plate is placed in just between the flow path of the oil and gas between the main tank pipe mouth and the conservator pipe mouth. A mercury switch is placed on this flap. When there is movement is the flap due to the movement of oil then the terminals of the mercury switch makes contact with the trip circuit’s terminal and thus completes the trip circuit. This will opens the circuit breaker to disconnect the supply.

The Buchholz relay’s vessel contains a release tap at the top, to exhale the extra gas from creating any types of damage due to pressure.

Working of Buchholz relay

The working principle of Buchholz relay depends upon the generation of hydrogen gas (H2) inside the transformer oil tank due to internal fault. When the transformer oil is exposed to a considerable amount of heat, then it gets decomposed and produces hydrogen gas (H2).

If any fault occurs inside the transformer, then a large amount of heat will be produced. The heat generated will decompose some part of the transformer’s oil in the main oil tank. The hydrogen gas (H2) will be generated due to the decomposition of oil inside the tank.

As hydrogen gas (H2) is lighter than the oil, it moves upwards towards the conservator tank through the pipeline. The Buchholz relay is connected in the pipeline between the main tank and the conservator tank. When gas entered the relay from the transformer main tank, some amount of gas is entrapped by the upper portion of the Buchholz relay.

The amount of hydrogen gas generated depends upon the amount of heat generated. If more amount of heat is generated then more amount of H2 is generated. Therefore more gas will be accumulated inside the relay chamber. When the amount of H2 gas tends to approach a predetermined safe value, then it creates a pressure to the float which leads to tilt the flap. After the movement of the flap, the upper mercury switch will get closed circuited. This will complete the alarm circuit. This is how the alarm circuit is working under any faulty condition.

If a severe fault occurs inside the transformer, then a large amount of heat will be produced inside the transformer main tank. This large amount of heat will decompose the oil. Hence a large amount of H2 gas will be generated.

This large amount of H2 gas rushes upwards towards the conservator tank via Buchholz relay. This will tilt the lower part flap. Due to movement of the flap, the mercury switch terminals will complete the trip circuit and open the circuit breaker operating the transformer. This is how the trip circuit is working under any severe faulty condition.

Summary

Occurrence of fault ⇒ Decomposition of transformer oil ⇒ Generation of H2 gas ⇒ Entrapping in relay chamber ⇒ Movement of flap ⇒ Trip circuit.

Advantages of Buchholz relay

1. This relay senses the internal developing faults in a transformer at an early stage. Hence it protects the costly oil-immersed transformers from damage.

2. The operation and handling of this relay are quite easy.

Limitations of Buchholz relay

1. This relay is used only in the oil-immersed transformers.

2. Using this relay in transformers for rating less than 500 KVA is uneconomical.

3. It can only detect the fault below the oil level.

4. The response time of this relay is high.

Image reference: Quora