Fuse was patented by Thomas Edison in 1890. Fuse is the simplest & cheapest device used for interrupting an electrical circuit under short circuit or excessive. The fuse element is generally made of materials having low melting point, high conductivity and least deterioration due to oxidation e.g., silver, copper etc.

Definition of fuse

It is a device used for protecting appliances, cables, and electrical equipments against short circuits and/or overloads. Whenever the current flowing in the circuit exceeds a certain predetermined value, fuse breaks the circuit by melting or fusing fuse element ( a piece of thin metal wire).

Fuse Element

It is the part of the fuse which melts whenever current flowing in the circuit exceeds a certain predetermined value. The material used for fuses are lead-tin alloy and copper for low currents and silver for currents above 15 A.

Rated current of a fuse is the current that a fuse can carry continuously without melting of fuse element.

Minimum Fusing current is the minimum current (RMS value) at which fuse wire or element will melt.

The fusing current depends upon the various factors such as :

- material of fuse element

- length – the smaller the length, the greater the current because a short fuse can easily conduct away all the heat

- diameter

- size and location of terminals

- previous history

- type of enclosure used

Fusing factor is the ratio of minimum fusing current to the rated current. This factor is always greater than 1.

Prospective current of fuse is the value of current which will flow through it just before the melting of the fuse wire under short circuit condition.

Cut-off current is the instantaneous current at which the fuse element or wire melts.

Pre-arcing time is the time taken by a fuse wire to be broken by melting. It is measured from the instant; the over current starts to flow through fuse, to the instant when fuse wire is just broken by melting. Pre-arcing time is also known as melting time.

Arcing time is the time taken from the instant of arc initiation to the instant when circuit current becomes zero.

Total operating time of fuse is the sum of Pre-arcing and arcing time.

Characteristics of fuse

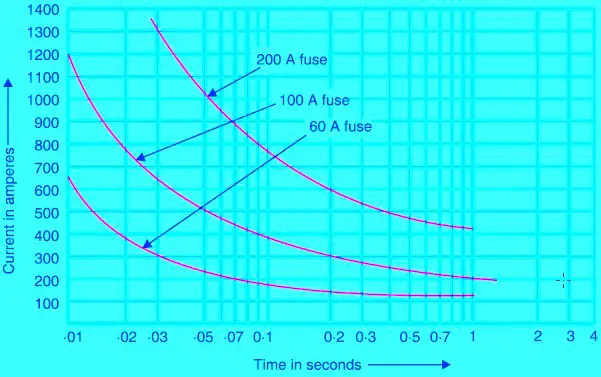

Fuse time current characteristic is shown in fig. 2. The time required to blow out the fuse depends upon the magnitude of excessive current. The greater the current, the smaller is the time taken by the fuse to blow out (or fuse element to melt). In other words, as the current increases, the pre-arcing time decreases.

In the above figure, curve for three Fuses of rating 60 A, 100 A and 200 A are given. We select Fuse of rating 60 A for the sake of understanding. See, if the current flowing through the Fuse element is around 350 A then the Fuse element will melt in .02 sec i.e. 20 ms while if the current is around 225 A then it will take 50 ms to melt.

Advantages of fuse

1. It is the cheapest form of protection available.

2. It requires no maintenance.

3. Its operation is inherently completely automatic unlike a circuit breaker which requires an elaborate equipment for automatic action.

4. It can break heavy short-circuit currents without noise or smoke.

Disadvantages of fuse

1. Considerable time is lost in rewiring or replacing a fuse after operation.

2. On heavy short-circuits, discrimination between fuses in series cannot be obtained unless there is sufficient difference in the sizes of the fuses concerned.

3. The current-time characteristic of a fuse cannot always be co-related with that of the protected apparatus.

Types of Fuses

A). Rewirable type fuse

B). Cartidge or totally enclosed fuse

Other classification of Fuses

- AC Fuse

- DC Fuse

This classification of Fuse arises because of arcing. In DC it is quite time taking to extinguish the arc. Therefore DC Fuses are made with longer wire so as to avoid arc. Hence DC Fuses are bigger in size. But in AC fuse as the current reduces to zero in every haft cycle (10 ms assuming 50 Hz frequency), arc is extinguished.