A generating station in which diesel engine is used as the prime mover for the generation of electrical energy is known as diesel power plant or diesel power station.

In a diesel power plant, a diesel engine is used as the prime mover. The diesel burns inside the engine and the products of this combustion act as the “working fluid” to produce mechanical energy. The diesel engine drives the alternator which converts mechanical energy into electrical energy. As the generation cost is considerable due to a high price of diesel, therefore, such power stations are only used to produce small power.

Although steam power plants and hydroelectric plants are invariably used to generate bulk power at cheaper cost, yet diesel power stations are finding favour at places where the demand for power is less, sufficient quantity of coal and water is not available and the transportation facilities are inadequate. These plants are also used as standby sets for continuity of supply to important points such as hospitals, radio stations, cinema houses and telephone exchanges.

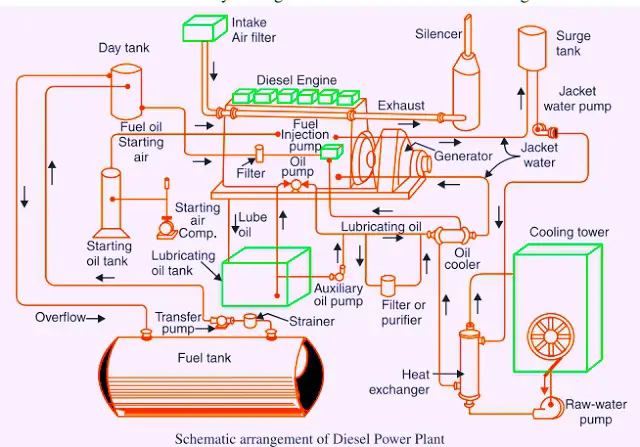

Schematic Arrangement of Diesel Power Plant/Station

The following Figure. shows the schematic arrangement of a typical diesel power plant/station.

Apart from the diesel generator set, the plant has the following auxiliaries:

1. Fuel supply system

It consists of a storage tank, strainers, fuel transfer pump and all day fuel tank. The fuel oil is supplied at the plant site by rail or road. This oil is stored in the storage tank. From the storage tank, oil is pumped to smaller all day tank at daily or short intervals. From this tank, fuel oil is passed through strainers to remove suspended impurities. The clean oil is injected into the engine by fuel injection pump.

2. Air intake system

This system supplies necessary air to the engine for fuel combustion. It consists of pipes for the supply of fresh air to the engine manifold. Filters are provided to remove dust particles from the air which may act as abrasive in the engine cylinder.

3. Exhaust system

This system leads the engine exhaust gas outside the building and discharges it into the atmosphere. A silencer is usually incorporated in the system to reduce the noise level.

4. Cooling system

The heat released by the burning of fuel in the engine cylinder is partially converted into work. The remainder part of the heat passes through the cylinder walls, piston, rings etc. and may cause damage to the system. In order to keep the temperature of the engine parts within the safe operating limits, cooling is provided. The cooling system consists of a water source, pump and cooling towers. The pump circulates water through a cylinder and head jacket. The water takes away heat from the engine and itself become hot. The hot water is cooled by cooling towers and is recirculated for cooling.

5. Lubricating system

This system minimises the wear of rubbing surfaces of the engine. It comprises of lubricating oil tank, pump, filter and oil cooler. The lubricating oil is drawn from the lubricating oil tank by the pump and is passed through filters to remove impurities. The clean lubricating oil is delivered to the points which require lubrication. The oil coolers incorporated in the system keep the temperature of the oil low.

6. Engine starting system

This is an arrangement to rotate the engine initially while starting until firing starts and the unit runs with its own power. Small sets are started manually by handles but for larger units, compressed air is used for starting. In the latter case, air at high pressure is admitted to a few of the cylinders, making them act as reciprocating air motors to turn over the engine shaft. The fuel is admitted to the remaining cylinders which make the engine to start under its own power.

Maintenance of Diesel Power Plant

At the time of diesel engine or diesel-electric power plant, following points are considered during a maintenance period.

- To maintain the operating condition of a diesel engine at every half hour.

- To maintain the correct record of the instrument reading in the log sheet.

- To maintain the record of instrument temperature, pressure, electrical load, flow etc.

- To check the level of fuel oil periodically.

- Filtered the fuel and remove unwanted impurities.

- Clean the fuel tank at regular interval.

Advantages of Diesel Power Plant/Station

- The design and layout of the plant are quite simple.

- It occupies less space as the number and size of the auxiliaries is small.

- It can be located at any place.

- The overall cost is much less than that of steam power station of the same capacity.

- It requires less quantity of water for cooling.

- It requires less operating staff.

- It can be started quickly and can pick up load in a short time.

- There are no standby losses.

- The thermal efficiency of the plant is higher than that of a steam power station.

Disadvantages of Diesel Power Plant/Station

- The plant has high running charges as the fuel (i.e., diesel) used is costly.

- The plant can only generate small power.

- The maintenance charges are generally high.

- The plant does not work satisfactorily under overload conditions for a longer period.

- The cost of lubrication is generally high.

Applications of Diesel Power Plant

1. The diesel oil is used as a fuel in power generation.

2. It produces AC as well as DC Voltages.

3. It is used where small power generation is a requirement.

4. In case of any emergency diesel engines are used.

5. It is also used for peal load during a small period of time.

6. It is used to restart the boilers.

7. It is used in remote places.

8. It can be used in areas having low load factor.

Exercise

Q. Explain how diesel power plants are used for starting power plants.

Answer. At the time of starting a new plant, when station auxiliaries etc. are not fed from other sources, diesel plant is used to supply auxiliaries of the plant. When auxiliaries are run, power can be started & generate electricity. The same action will take place at the time of breakdown of the plant, etc.

Q. State how diesel power plant can be used as peak load plants?

Answer. As diesel power plant takes no time to start and stop. It can be connected to the system at the time of peak load and normal load. It is not economical to use them during normal loading as their generating cost is high.

Q. Write meaning of Captive Power Generation

Answer. Captive generating plant means a power plant set up by any person to generate electricity primarily for his or her own use and includes a power plant set up by any co-operative society or association of persons for generating electricity primarily for use by members of such co-operative society or association.